Coffee Table

Introduction

This coffee table was primarily made with salvaged wood; the legs, which are pine, were bought as 2*4s. The table top is composed of six different pieces of wood that have been glued and attached using mortise and tenon joints. This was a collaborative effort from James Spence and myself. I assembled the pieces and designed the table. We relied on James' knowledge of carpentry to build it.

Preparation

Preparation involved searching through a dumpster outside of a house that was having its basement gutted. I probed the bin for salvageable pieces of metal or wood. I found a large piece of red-stained wood. It looked like it had recently been used as a mantle or a shelf. I then found a shelf unit with small, thin doors. The shelf had been amorphized from the weight of other objects, including brick, discarded on top of it. After uncovering it from the rubble, I pulled its doors off.

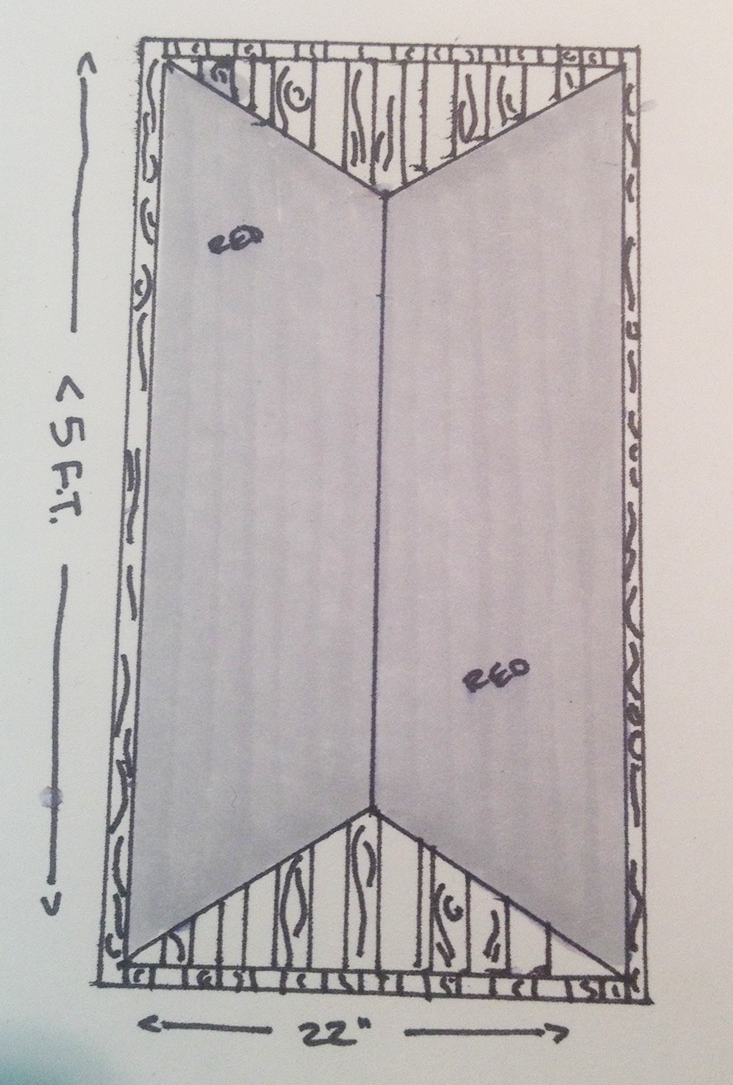

With the materials at hand, I began imagining their re-employment. Their use as a table was one of my first thoughts because of the size and weight of the red-stained piece. James and I looked at a couple spaces whose purpose could use a table or be made to incorporate one. We explored different combinations of the wood. I sketched out different ways I might combine the items with one another and then incorporate the object into a space. Ultimately, we found a space that needed a coffee table, so that’s what we built.

Stages

Stage 1: Sketch

Stage 2: Assemble

Notes: For the wood with cracks down the line, we glued two pieces on top of one another to strengthen the particular section, while keeping the cracked pieces on the bottom of the table in the final product.

Stage 3: Shape

Stage 4: Attach

Notes: The joining wood is held together at the seams with mortise and tenon joints and wood glue. The wood glue connects wood fibres stronger than they're connected themselves. During this stage, we learned that the glue doesn't congeal in the cold. We moved the pieces inside from the garage so that the pieces would solidify and the glue would dry overnight.

Stage 5: Sand

Notes: This stage was especially important for our project because we attached six different pieces of wood together to form the tabletop. We had to ensure that the transitions were smooth from each solid piece of wood to the next so that someone wouldn't spill their drink or get a sliver from an inconsistency in the surface.

Stage 6: Apply finish

Notes: Different woods react differently to the same stain. I had to play around with the number of coats because of the different kinds of wood on the the same surface. There is a noticeable difference from one solid piece of wood the next, but it adds character.

Final Work

Conclusion

James and I worked on this table for about a month. I learned about turning a conceptual model into a physical object. I had to communicate my idea, not just through drawing, but also through face-to-face communication.

Questions fuel progress and project success. There were details about this table I didn't know existed until we ran into them during the building process. Just because they don't exist in a rendering or conceptual model, doesn't mean they won't exist in the final product and cause issue if you ignore them. What it meant for me, though, was that my sketches were facile, but I didn't know that until we started building.

It was a great learning experience. I felt a bit like Wall-e from the 2008 Pixar animation film WALL-E. Here I was with this inefficient system that saw the basement of a house gutted and reduced essentially to rubble or waste. I was tasked with finding value in the rubble, just as Wall-e strived to. He re-employed the world's waste into tools, toys, and knick-knacks he found to be useful or entertaining. I will apply the lessons I learned from this project and Wall-e's ingenuity to my next endeavours.